How does the APQP method effectively secure the critical phases of complex industrial projects?

The information available centrally in real time guarantees the coherence of the product documentation and enables production choices to be adjusted.

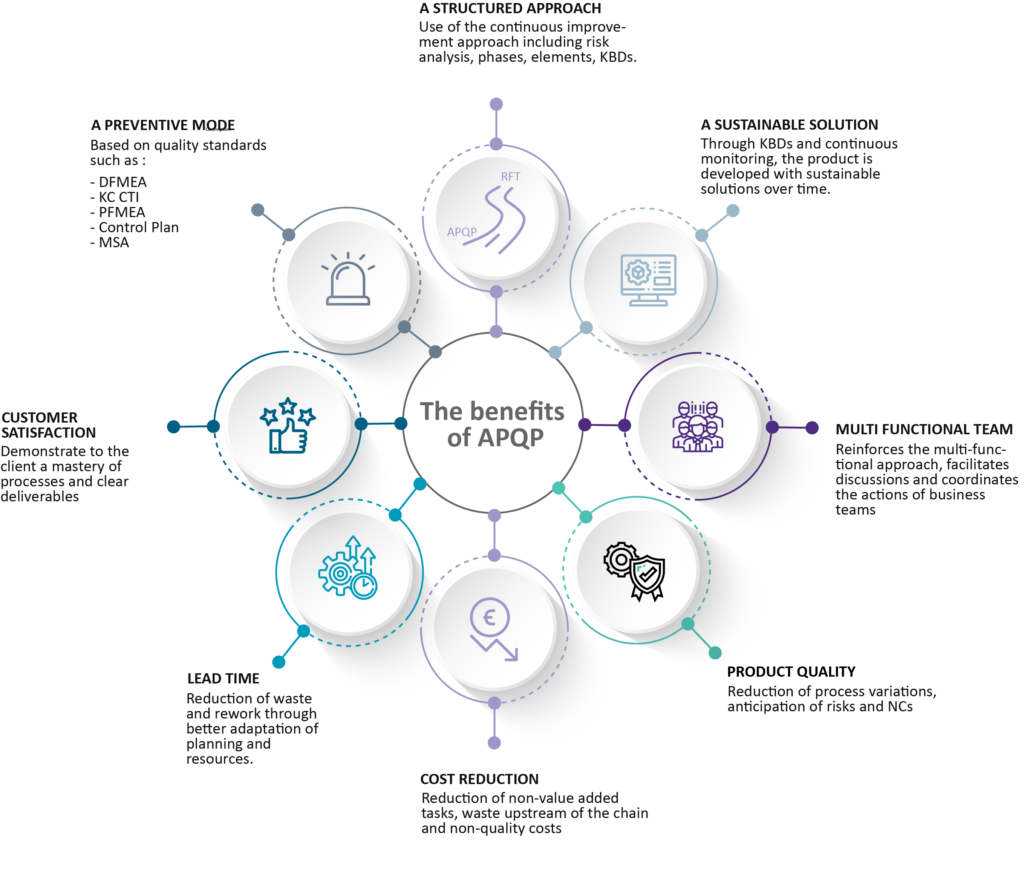

Avoiding errors rather than having to correct them is the leitmotif of up-front quality planning.

APQP according to Scalian

Our approach

Scalian’s APQP community offers a pragmatic and structured approach to increasing the maturity of the entire supply chain.

Introduction of new products

- Project management

- Project quality assurance

- Validation of APQP deliverables

- Facilitation of workshops

Industrial transfer

- Project management

- Project quality assurance

- Validation of APQP deliverables

APQP deployment

- Maturity diagnosis

- Deployment roadmap

- Pilot project

- Skills assessment, training and coaching

- Integration into the management system

- Digitisation of processes

Supply chain

- Supplier maturity diagnosis

- Supplier development

- Validation of APQP deliverables

Our method

Associated with project management, the APQP is deployed by taking into account the following steps:

- programme definition and planning

- design and development of the product

- design and development of the associated production process

- presentation and validation of the parts file

- analysis of feedback information

- implementation of improvement actions

Unleash your potential

with Scalian

Join passionate men and women.

Develop yourself in an organisation where professionalism and entrepreneurship go hand in hand with kindness and caring.