In 2013, we noted that in order to produce a return on investment in operations, drones had to be safe, reliable, secure, but also automatic and autonomous in decision making. In order to move to an industrial scale, we had to immediately consider not one drone but several, at least, to ensure a replacement or continuity of operations.

Today, this technology is integrated into several systems by the teams of the Unmanned System division, which we created in 2016, specialising in advanced drone-based systems and which is continuing its development and commercialisation through various projects. This is notably the case for Metis, which embeds this technology, selected by Total in 2017 for its maturity and its ability to meet the needs of the drone fleet system.

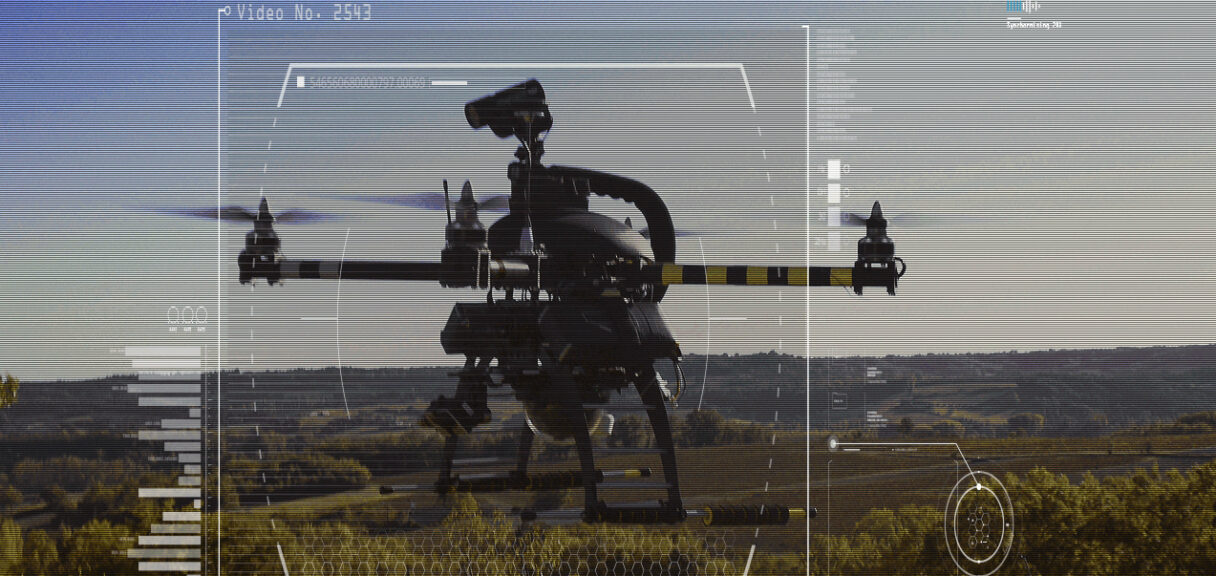

EZ CHAINS is a technology embedded in drones that gives them autonomy of decision and collaboration capabilities between them. This technology is designed to be safe and to automate drone operations in order to meet mission objectives or to adapt them dynamically, without the necessity of remote pilots, or rather by elevating them to the position of last resort in charge of taking control of the aircraft, essentially for regulatory reasons. Because, out of sight or at night, and even sometimes in close proximity, the pilot is unable to do more than the drone itself.

EZ-CHAINS is presented as a companion computer with a small hardware and a set of software. But it can also be integrated into an existing software architecture with a hypervisor OS if it would guarantee enough CPU bandwidth to the EZ-CHAINS partition.

Dropping simulation

EZ-CHAINS is first of all a software for safety and navigation functions, based on all the equipment, sensors and actuators in the UAV. This software gives the drone on-board decision making capabilities, allowing it for example to evolve in authorized zones, to avoid forbidden zones, to continue its navigation in the absence of radio communication, to look for an emergency landing area in its close environment, or to adapt its navigation according to information coming from the ground or from its payload. In the case of METIS, each drone will select and adapt its dropping points according to the duration of the flight, its battery charge and the situation on the ground such as clear overflight area, exclusion zones, mandatory paths, or secured areas, or even take off only when no human is within 6 meters, thanks to an embedded Lidar. More generally, this software will ensure all the failsafe decisions without stopping the mission.

his software implements a multi-agent system architecture, where the decision is not centralised but distributed in each of the UAVs according to the information, stimuli, actions, roles and capabilities related to its individual configuration. Each agent will share its information with the other agents in order to achieve the overall mission objective in the best conditions.

Through collaboration with other systems and objects, in which I obviously include other identified aircraft, this allows complex missions to be carried out, which last over time, are resilient to hazards, with a high level of service. The drones and the systems that implement them can therefore achieve a level of operation guaranteed by the continuity and permanent adaptation of the mission.

With this agnostic drone technology, drones can be made to work together for formation flights, as well as to synchronise the capture of multiple cameras and guarantee in real time the geographical overlap of shots or their temporal synchronisation. It is also possible to define behaviours in swarms or fleets, so as to guarantee a quality or continuity of service or a multiplication of the tasks carried out. It is also possible to aggregate the skills of specialised drones to carry out complex missions.

Advanced functions

EZ-CHAINS has a software architecture with multiple technical or functional components that can be aggregated according to the services and capabilities that the system needs to offer to operators or required to perform operations under defined conditions. In addition to the automatic navigation, static or dynamic geofencing and safety fallback functions already mentioned, EZ-CHAINS has functions for precision landing, RTK GPS information sharing, Detection Recognition Identification, object or individual tracking, and use of mesh radio networks. Other complementary components are also in preparation to continue to secure and automate operations, with the control of the electromagnetic signature of the area of evolution, and the taking into account of weather stations or information systems such as UTM.

EZ-CHAINS is also a tool chain that allows the preparation of a mission, its complete simulation with the possibility of implementing real components in SITL or HITL tests and generating faults, damages or flight conditions that it is not possible to carry out in real life, and thus verify the behaviour of the system in these situations. These same tools allow the supervision of the mission throughout its running phase, offering a digital twin of the whole fleet, with the possibility to act in real time with high level commands.

COMP4DRONES

To go further in the modularity of UAV and operations systems with a high level of safety by design, Scalian has been contributing since 2019 to the COMP4DRONES project with 50 other European partners, including Altran/CapGemini Engineering, and is working to make EZ-CHAINS components safer and more interoperable with those of other players. The objective of the project is to demonstrate that the design of systems and their implementation benefit from gains in terms of safety, reliability, security, costs at completion, but also industrialisation and productivity of UAV-based systems in civilian use.

In conclusion

This technology, as you may have understood, is a “middleware – orchestrator” for drones and, more widely, for robotics or smart objects. Scalian, as the provider of this technology, collaborates with Cap Gemini Engineering in digital transformation projects, where drones, as precise and automated tools, provide a real industrial solution in the value chain of the final customer.